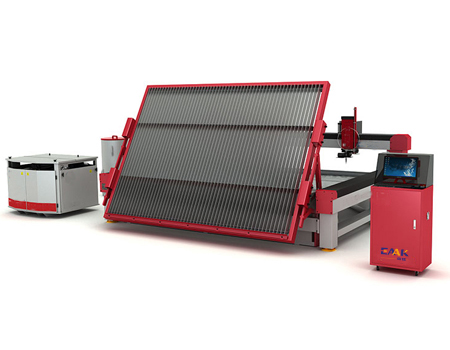

Waterjet glass cutting machine

EAAK water jet cutter application:

Cutting materials are not limited (stainless steel, steel, copper, aluminum and other metals, glass steel, stone, glass, ceramics, plastics, composite materials...), waterjet cutting is currently the most applicable cutting process;

| Metal cutting: | |

| 1 | Decoration of stainless steel,aluminum.iron,brass and other metal cutting process. |

| 2 | Manufacture of machinery and equipment control cabinets such as food machinery,medical machinery,CNC machinery. |

| 3 | The metal parts cutting such as stainlesssteel flange,semi-finished,steel construction, non-ferrous metal and so on. |

| Glass cutting: | |

| 1 | Gas stove surfaces, range hood,disinfecting cabinet, TV, bathroom products. |

| 2 | Construction and decoration glass,automotive glass. |

| Ceramic and stone cutting: | |

| 1 | Ceramic cutting for decoration and construction. |

| 2 | Marble mosaic,granite mosaicmstone plate cutting. |

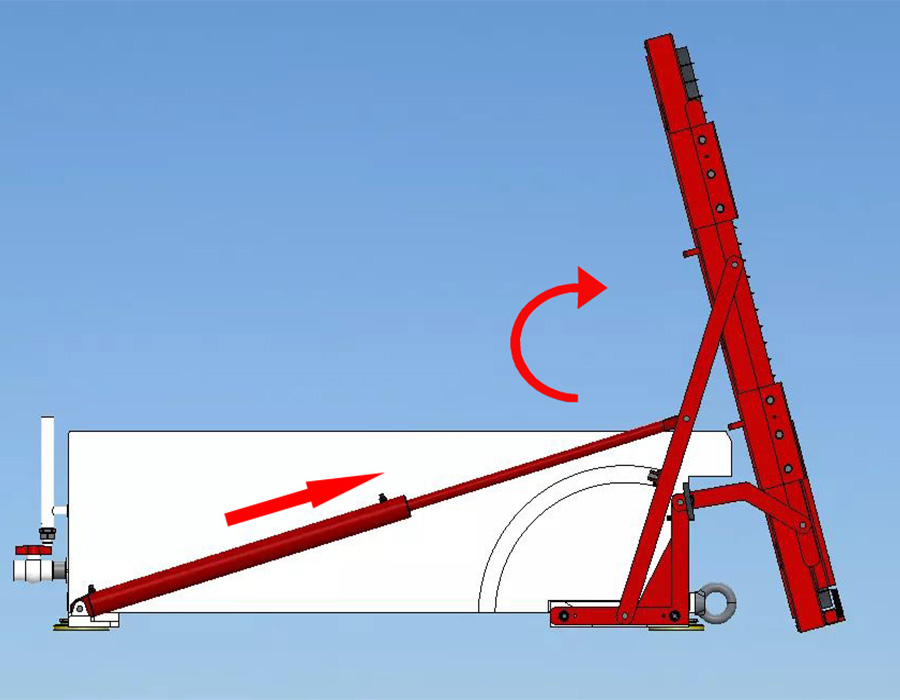

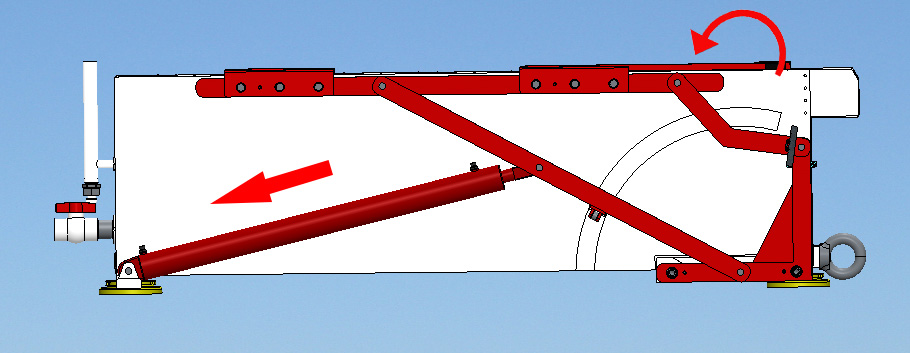

The lifting platform is specifically designed to solve the handling problems of large glass after processing. This platform can cut glass up to 4000 mm, the platform load is 1000 kg, the maximum angle of rotation is 85 degrees, and the hydraulic lifting method is adopted. After the glass is cut on the ordinary water cutter platform, especially after cutting a large number of irregular holes on the glass, the breakage rate of the glass during the process of glass uplifting is quite high, which is the most popular in the market. The cutting of tempered glass countertops is most obvious. Under the unanimous recommendation of the customers of glass deep processing, the glass cutting and turning platform has finally been successfully designed. At present, many problems have been solved for domestic and foreign glass deep processing customers, and the equipment has been well received by users.

| Feature of gantry structure water jet cutting worktable: | |

| 1 | Gantry structure, beautiful appearance, reasonable structure design, with good rigidity and stability, even by force.Smooth operation, accurate and safe. |

| 2 | Machine bed and the load-bearing platform sub-structure, load-bearing platform will not affect the long-term stress changes in machine tool accuracy,NC sports institutions and support the workpiece table for sub-structure, to put an end to the cutting process due to water flowing in the right Degrees of movement. |

| 3 | Cutting platform X beam (gantry) using disposable aluminum extrusion.Gold material, light weight, steel is strong, and without deformation. Is water cutting machine.The most advanced technology. |

| 4 | The X, Y, Z three-axis are canceled dust folding, the Y-axis towline Built-in Results Structure, such structure can significantly improve the service life of the machine to reduce the use and maintenance cost. The countries that adopted.The occasion of the most popular design concept, the direction of development of water jet cutting machine. High quality care chain and a dedicated cable, the Durable, and high reliability. |

| 5 | Drive motor and ball screw connected by a flexible coupling directly connected, rather thanIt torsionally rigid coupling, compared with the advantages of Reversible absorb vibration, transmission,Higher accuracy. |

| 6 | International brand of high quality ball screw, linear motion guide drive mechanism to ensure that the velocity of the cutting headAnd accuracy of 3m above itinerary using turn Nut transmission. Long distance transmission more reliable over-travel automatically limit.Dual protection function and the soft limit. |

| 7 | Y to the bed structure castings and concrete structures,Metal part of the aging treatment by gantry planing, rail grinding, consumerIn addition to the micro-deformation, long to maintain the mechanical precision. |

| Model | EK3020R |

| X Y axis Working size | 3000mm*2000mm |

| Z working height | 150mm |

| Cutting Pressure | 420Mpa 37kw UHP pump |

| Control accuracy | 0.01mm |

| Cutting accuracy | 0.1-0.2mm |

| Repositioning Accuracy | 0.05mm |

| Max cutting thickness | 300mm(depends on materials) |

| Max. moving speed | 6000mm/min |

| Power supply | 380V 50Hz |

| Environmental temperature | -10-50°C |

| Max flow rate | 3.7L/min |

| Max oil discharge | 206L/min |

| Max delivery capacity of oil pump | 106L/min |

| Control system | Ncstudio (Shanghai) software IPC controller |

| CAD/CAM software | AutoCAD,ArtCAM |

| Drive motor | Japan Yaskawa servo drive motor |

Parameters of CNC waterjet cutter working on different materials such as glass,metal,stone(as follows)

| Materials | Thickness | Cutting speed (mm/min) | ||

| 380Mpa | 420Mpa | 600Mpa | ||

| Normal glass cutting | 6 mm | 1400-1500 | 2100-2250 | 2520-2700 |

| 8 mm | 690-800 | 1035-1200 | 1242-1440 | |

| 19mm | 400-500 | 600-750 | 950-1150 | |

| Granite panel cutting | 20mm | 260-300 | 390-450 | 468-540 |

| 30mm | 170-200 | 255-300 | 306-360 | |

| Porcelain tile cutting | 10mm | 900-1000 | 1350-1500 | 1620-1800 |

| Marble panel cutting | 10mm | 600-900 | 900-1350 | 1080-1620 |

| 20mm | 350-400 | 526-600 | 630-720 | |

| 30mm | 260-300 | 390-450 | 468-540 | |

| Laminating glass cutting | 21mm | 490-600 | 735-900 | 882-1080 |

| Sponge and foam cutting | 20mm | 6000-7000 | 9000-10500 | 10800-12600 |

| 50mm | 2600-3000 | 3900-4500 | 4680-5400 | |

| 80mm | 1600-2000 | 2400-3000 | 2880-3600 | |

| Steel plate cutting | 10mm | 170-220 | 255-330 | 306-396 |

| 20mm | 75-100 | 113-150 | 135-180 | |

| 30mm | 15-30 | 22-45 | 27-54 | |

| Stainless steel plate cutting | 1 mm | 1000-1200 | 1500-1800 | 1800-2160 |

| 3 mm | 500-600 | 750-900 | 900-1080 | |

| 6 mm | 240-300 | 360-450 | 432-540 | |

| 10mm | 150-180 | 225-270 | 270-324 | |

| 16mm | 85-100 | 128-150 | 153-180 | |

| 20mm | 70-80 | 105-120 | 126-144 | |

| 30mm | 30-40 | 45-60 | 54-72 | |

| Copper plate cutting | 3 mm | 1350-1500 | 2025-2250 | 2430-2700 |

| 5 mm | 700-850 | 1050-1275 | 1260-1530 | |

| 20mm | 160-200 | 240-300 | 288-360 | |

| 30mm | 100-120 | 150-180 | 180-216 | |

| Titanium alloy cutting | 13mm | 100-115 | 150-173 | 180-207 |

- 上一篇:没有了

- 下一篇:Marble CNC waterjet cutter