Causes and treatment of oil temperature rise in waterjet supercharger system

Post time:2023-02-03 By:EAAK Clicks:

|

First, the dangers of high oil temperature

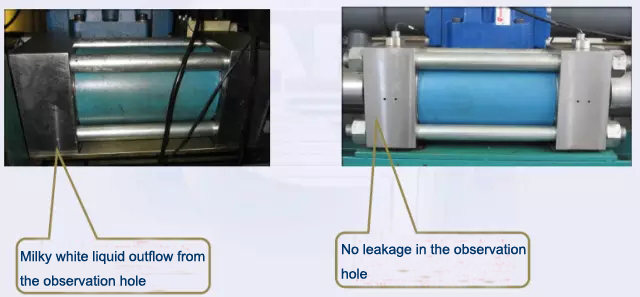

1,Hydraulic oil viscosity, volumetric efficiency, and hydraulic system work efficiency all decrease, leakage increases, and even mechanical equipment can not work normally.

|

| 2,The components of the hydraulic system expand due to overheating, which damages the original normal fit clearance of the relative moving parts, resulting in increased frictional resistance and easy jamming of the hydraulic valve. At the same time, the lubricant film becomes thinner and mechanical wear increases. Precise mating surfaces of motors, etc. may cause failure or scrap due to premature wear. |

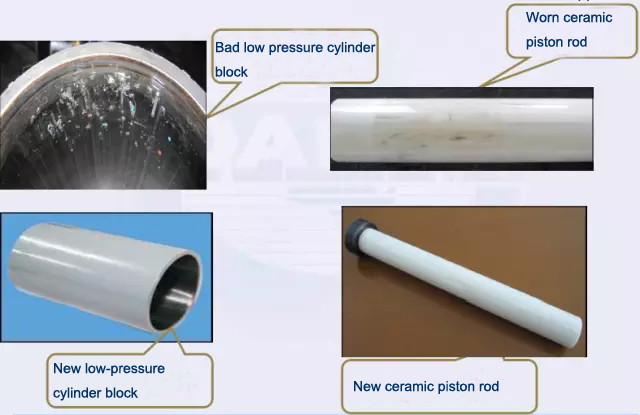

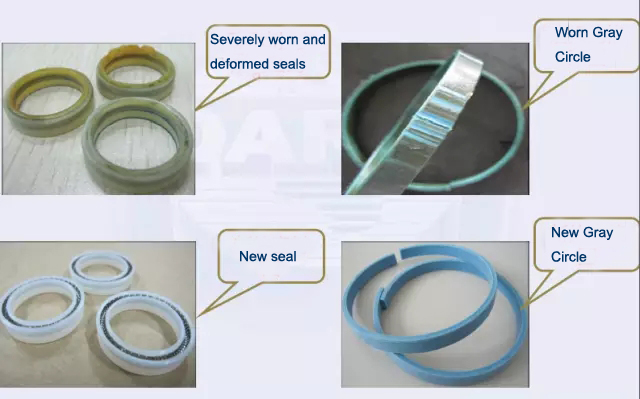

| 3,Accelerate the aging and deterioration of rubber seals, shorten the life, until the sealing performance is lost: the lighter causes severe leakage of the hydraulic system, and the serious causes the hydraulic system piston, low-pressure cylinder and other strains. |

|

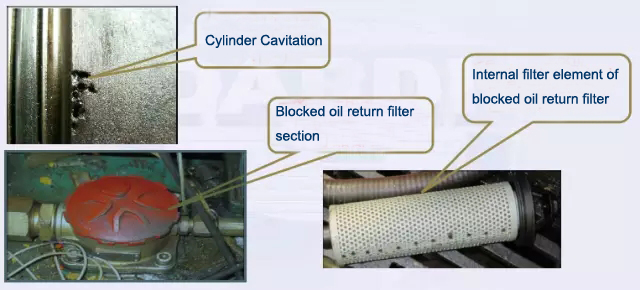

4,Evaporation of oil and evaporation of water easily cause cavitation of hydraulic components; oil oxidizes to form gelatinous deposits, which can easily block small holes in oil filters and hydraulic valves, so that the hydraulic system cannot work normally.

Therefore, the high temperature of hydraulic oil will seriously affect the normal use of the machine, reduce the service life of hydraulic components, and increase the maintenance cost of engineering machinery.

|

|

Cavitation: Mainly refers to small holes formed by pitting and needle-like holes formed on the machinery due to long-term engineering use, resulting in the outer layer of the machinery falling off. Generally unavoidable.

Second, the reason for the rise in oil temperature

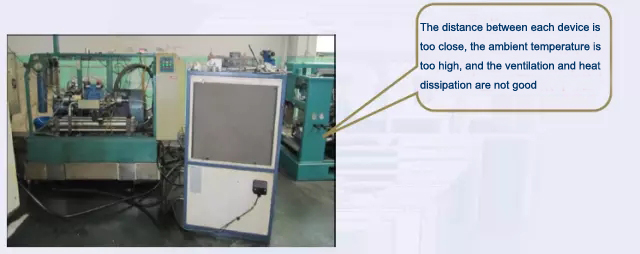

1,The fuel tank is installed near a high-temperature heat radiation source and the ambient temperature is high

|

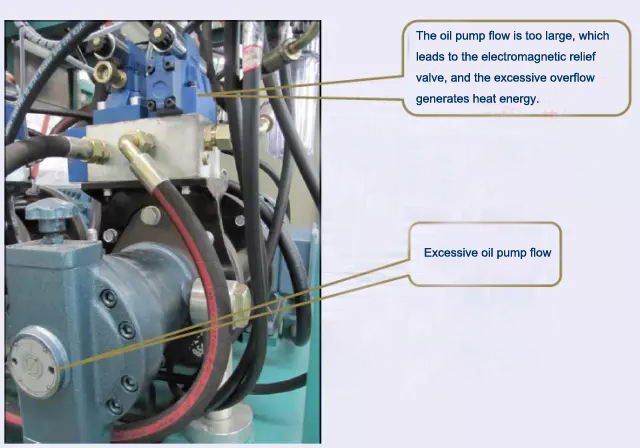

| 2,Large energy conversion caused by various pressure losses (such as overflow, pressure reduction, etc.) |

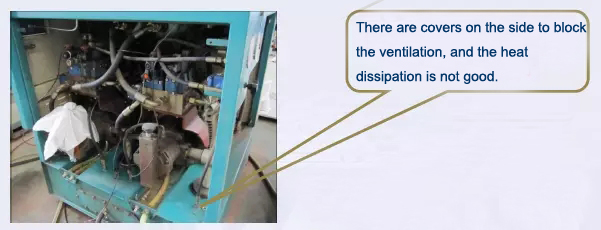

| 3,Enough heat dissipation area when designing the fuel tank |

|

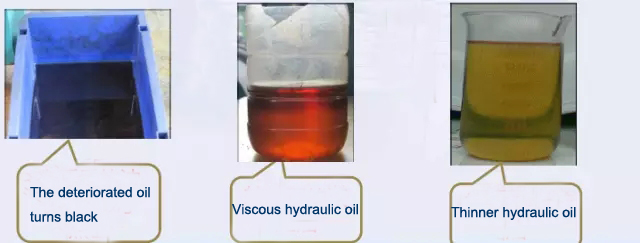

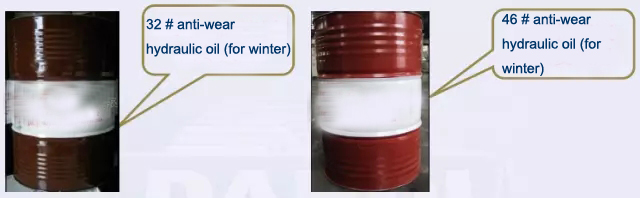

4,The oil is deteriorated or the viscosity of the oil is selected 丌 appropriate. The deteriorated oil turns black

Viscous hydraulic oil

|

|

How to control oil temperature rise of water jet cutting machine high pressure pump.

1,Try to avoid heat sources and place in a well-ventilated place;

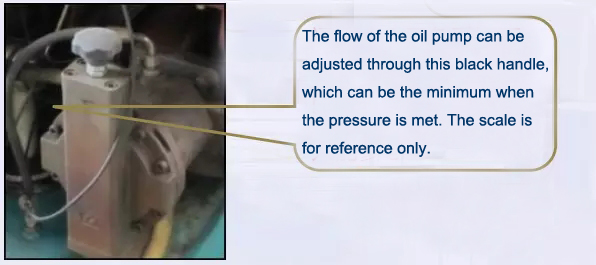

2,Adjust the oil pump flow to reduce high pressure overflow loss and reduce system heating;

|

|

Note: Please adjust the oil pump flow in the off state.

3,Select the hydraulic components of the original regular manufacturer;

4,Correctly select oil viscosity;

|

|

Note: When the new equipment is used for about 6 months, the fuel tank should be cleaned and replaced with new oil, and the new oil should be replaced once a year in the future

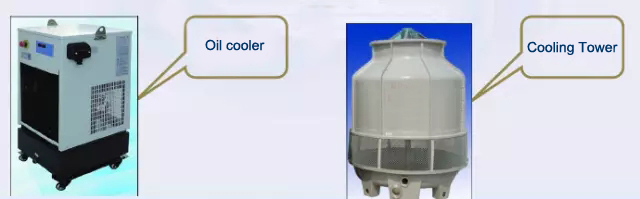

5,Oil cooler can be installed near the high temperature heat source or when the equipment is continuously working for a long time.

|

Recommended Reading

Portable water jet cutting machine for mixing abrasive in advance

Pre-mixed abrasive portable water jet cutting machine is to pre-mix abrasive and water, pressurize and deliver it to the ...

What are the characteristics of waterjet cutting seam?

What are the characteristics of the cutting seam and cutting section of the water jet? ...

Double units 420mpa pump Ultra high pressure water jet cutter

Double units 420mpa pump Ultra high pressure waterjet machine,with special strong structure and high pressure units,suit ...

What's the price of China cnc water jet cutting machine?

Good quality cnc waterjet cutter and lower price,china waterjet cutting machine give you easier choice....